Call: 08071269309

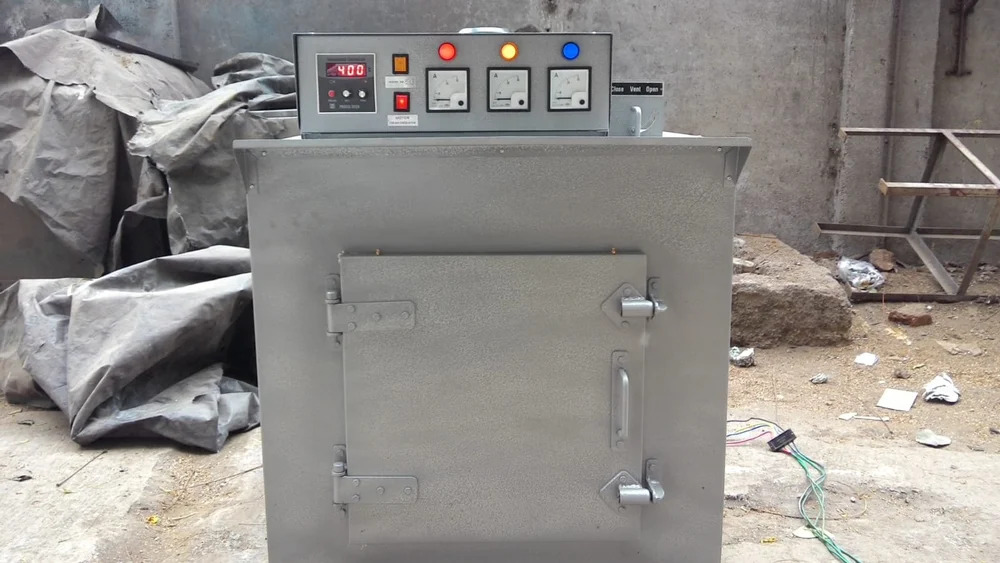

Flux Holding Ovens

Price 155000 INR/ Piece

MOQ : 1 Piece

Flux Holding Ovens Specification

- Condition

- New

- Usage

- Industrial

- Size

- Customized

- Weight

- 80-100 Kilograms (kg)

- Material

- Stainless Steel

- Voltage

- 220 Volt (v)

- Surface Finish

- Powder Coated

Flux Holding Ovens Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Flux Holding Ovens

Discover unmatched performance with Flux Holding Ovens, crafted from top-tier stainless steel and designed for seamless industrial use. Each oven boasts a sublime powder-coated finish and supports voltage requirements of 220 Volt (v), ensuring durability and excellent conductivity. Built to order with customizable sizing, these ovens weigh between 80-100 kg, making them robust yet versatile. Enjoy unbeatable value with Instant Checkout and attractive pricing from Indias foremost exporter, manufacturer, and supplier. Experience dependable quality and exceptional results at an unbeatable price point.

Versatile Commercial Applications

Flux Holding Ovens excel across diverse commercial settings, efficiently maintaining optimal temperatures for welding and manufacturing operations. These ovens are predominantly used in workshops, assembly lines, and fabrication facilities where precise control is paramount. The application method is straightforwardsimply load the oven, set the required temperature, and let it hold the flux in perfect condition, guaranteeing consistent quality for a range of industrial processes.

Main Domestic Market & Supply Logistics

Catering extensively to the domestic market, our order processing system ensures timely supply and smooth dispatching nationwide. With robust supply ability, we meet varying demands swiftly and efficiently. Sample policies facilitate customer assurance prior to bulk orders, streamlining decision making for clients. Our focus on efficient dispatch procedures and responsive service positions us as a top choice in the Indian supply chain for industrial holding ovens.

Versatile Commercial Applications

Flux Holding Ovens excel across diverse commercial settings, efficiently maintaining optimal temperatures for welding and manufacturing operations. These ovens are predominantly used in workshops, assembly lines, and fabrication facilities where precise control is paramount. The application method is straightforwardsimply load the oven, set the required temperature, and let it hold the flux in perfect condition, guaranteeing consistent quality for a range of industrial processes.

Main Domestic Market & Supply Logistics

Catering extensively to the domestic market, our order processing system ensures timely supply and smooth dispatching nationwide. With robust supply ability, we meet varying demands swiftly and efficiently. Sample policies facilitate customer assurance prior to bulk orders, streamlining decision making for clients. Our focus on efficient dispatch procedures and responsive service positions us as a top choice in the Indian supply chain for industrial holding ovens.

FAQs of Flux Holding Ovens:

Q: How is the Flux Holding Oven used in industrial applications?

A: The oven is used to maintain flux at a controlled temperature, preventing moisture absorption and ensuring welding processes yield consistent results.Q: What materials and finishes are available for the Flux Holding Ovens?

A: These ovens are made from stainless steel and feature a corrosion-resistant powder coated surface for enhanced durability and a superior aesthetic.Q: Where are Flux Holding Ovens typically installed within industrial settings?

A: They are commonly installed in workshops, fabrication plants, and manufacturing units to keep welding materials in peak condition.Q: What is the process for ordering and dispatching Flux Holding Ovens domestically?

A: Orders are processed quickly, and ovens are dispatched efficiently across India, supported by a reliable sample policy and robust supply capacity.Q: What are the main benefits of using Flux Holding Ovens?

A: Users benefit from improved welding quality, reduced waste, and safeguarded flux integrity, all at an unbeatable value and competitive pricing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Flux Oven Category

Flux Drying Ovens

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Voltage : 380 Volt (v)

Material : Stainless Steel

Weight : Upto 130 Kilograms (kg)

Flux Oven

Price 95000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Voltage : 220 Volt (v)

Material : Metal

Weight : Upto 52 Kilograms (kg)

Flux Baking Oven

Price 90000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Voltage : 220 Volt (v)

Material : Stainless Steel

Weight : Upto 50 Kilograms (kg)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese